RC photo paper and cast-coated photo paper are two common types of photo paper currently available. Both can be used to print photos, images, or promotional materials, and they look very similar externally. However, they still differ in manufacturing processes and paper structures.

Through this article, you will learn the basic characteristics of these two types of photo paper, helping you make wiser choices when struggling to select printing materials for different scenarios.

Next, let’s start with the structural principles of these two photo papers to gradually understand their differences.

Basic Structure and Features

RC Photo Paper

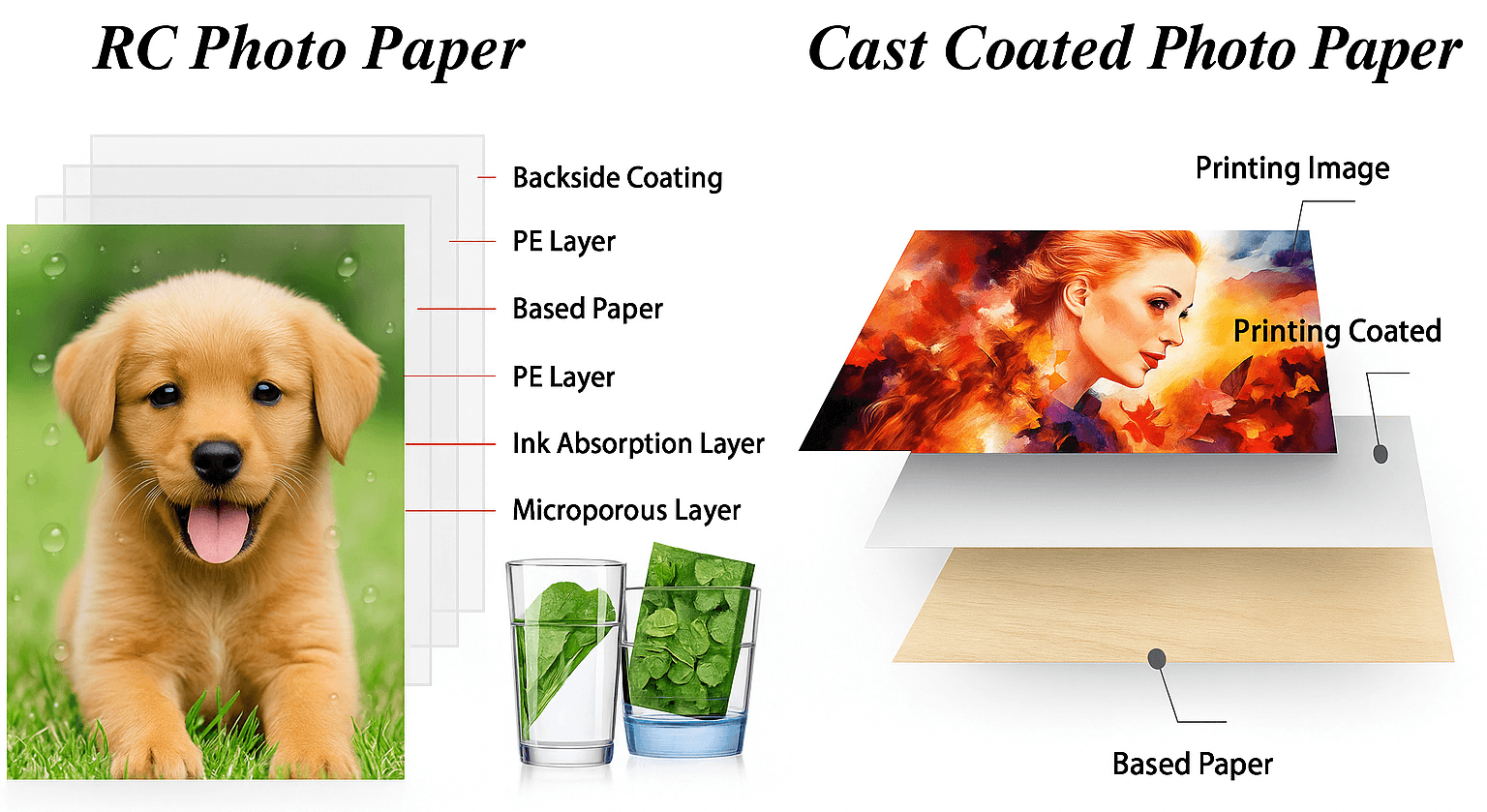

The “RC” in RC photo paper stands for Resin Coated. Its base material is a raw paper with polyethylene coated on both sides. This closed structure effectively blocks ink penetration, enhancing the paper’s stability and water resistance during printing.

On the printable side, RC photo paper also has an additional ink-receiving coating that quickly absorbs and locks ink droplets, ensuring sharp image edges and natural color transitions. These three layers—the resin seal layer, ink-receiving layer, and base paper substrate—together form the foundation of RC photo paper, providing excellent protective performance and expressiveness.

Thanks to this structural design, RC photo paper has the following significant advantages:

Excellent waterproof and moisture-proof properties: The double-sided resin layer effectively blocks environmental moisture and ink backflow, making the finished product more suitable for long-term preservation or hanging in spaces with large humidity changes.

Supports pigment ink printing: Compared to some papers with thinner ink-receiving layers, RC photo paper can stably carry high-concentration pigment inks, showing higher light resistance and fade resistance.

High stiffness and good hand feel: Common glossy RC photo paper of 260gsm is rigid and not prone to curling, suitable for hardcover photo albums, art picture books, and other occasions requiring binding or display.

High image clarity: The microporous coating allows finer control of ink droplets, with sharp image edges and natural layer transitions, making it ideal for photographic outputs that pursue detail reduction.

Precisely for these reasons, RC photo paper is favored by professional photographers and artists, especially for exhibition-grade photographic works, commercial advertising printing, and long-term photo preservation. In recent years, RC photo paper has also extended to various surface textures such as glossy, suede, and matte, flexibly adapting to the visual needs of diversified scenarios like art photography and commercial displays.

Cast Coated Photo Paper

The structure of cast-coated photo paper is relatively simple. It uses an unlaminated ordinary paper as the base, applies a layer of high-gloss coating slurry to the paper surface, and then dries it by contacting a heated metal drum, forming a mirror-like high-gloss layer on the surface. This method can enhance the color vividness and surface smoothness of images.

However, since it does not have a resin encapsulation layer like RC photo paper, cast-coated photo paper has relatively weaker moisture resistance and structural stability, prone to curling or ink bleeding in humid or high-temperature environments. Therefore, it is more suitable for short-term display or ordinary home printing where the required storage life is not high.

Cast-coated photo paper has the following characteristics:

High surface gloss: The cast-coating process brings a mirror-like reflective feel, with more vivid and transparent colors, suitable for color printing requiring strong visual effects.

Fast drying speed: The thin coating structure helps ink cure quickly, reducing smudges caused by hand contact or handling.

Lightweight and compatible: The paper has a moderate thickness, suitable for most home and office printers, with smooth paper feeding.

Low cost: Compared to RC photo paper, it has a lower cost and can be an economical choice for batch printing and daily use.

Although the process is relatively simple, cast-coated photo paper has a low manufacturing cost, and its printing colors can meet the needs of ordinary users, so many users still use it.

So, how do these structural differences specifically affect the printing experience? In the next section, we’ll compare them one by one in terms of printing quality, waterproof performance, drying speed, etc.

RC vs. Cast Coated

Conclusion

RC photo paper and cast-coated photo paper each have their advantages, suitable for different printing needs and scenarios. Understanding their differences can help you choose the most suitable photo paper according to specific applications.

Hopefully, this article has provided you with a reference for purchasing photo paper. If you have any questions during the purchase, please feel free to contact our pre-sales team, and we will provide you with the most professional and prompt service.

At the same time, we look forward to your continuous attention to the A-SUB blog. We will continue to share practical knowledge and selection guides in digital printing.

Thanks for your reading. 🙂

发表回复