In previous articles, we introduced what is DTF printing and its basic operation process. During the entire DTF transfer process, DTF powder plays a vital role—it acts as a bridge between ink and fabric. Only by choosing the right hot melt powder can ensure that the design adheres firmly to the fabric, improving the washability, softness and overall quality of the finished product.

This article will bring you together to explore the types, characteristics and points of use of DTF powders, and help you make more sensible powder choosing decisions in actual production.

What Is DTF Powder?

DTF powder is an indispensable adhesive material in the direct-to-film printing process, and its core role is to firmly adhere the printed pattern to the fabric surface. It is mainly composed of thermoplastic polyurethane (TPU) resin, pigments and various additives.

The TPU resin gives the powder good elasticity, abrasion resistance and weather resistance, enabling the transfer pattern to adapt to fabric stretching, folding and daily washing.

Pigment determines the color performance of the powder, common such as white, black, etc., through different ratios can achieve excellent coverage and visual effects.

Additives like leveling agents and stabilizers enhance the powder’s processing stability and transfer performance. They also boost fluidity, prevent caking, and ensure even spreading and smooth film formation.

After the printing pattern is completed, the powder is evenly spread on the back of the ink layer. It then undergoes melting and curing through hot pressure, which ultimately ensures the stable transfer of the pattern to the fabric surface.

Both the type and quality of the powder will affect the adhesion, softness and durability of the finished product. Therefore, choosing the right powder formulation is a prerequisite for realizing high-quality transfer results.

White vs. Black DTF Powders

The white and black hot melt powders are the two most commonly used base powders, they play a different but equally important role.

White DTF Powder

White powder is the preferred choice when dealing with white or light colored fabrics such as beige, light blue.

The core function of white powder is to achieve whitening of the base color and ink blocking. During the transfer process, it can effectively cover the base color of the fabric, especially on light or unevenly colored fabrics, to enhance the saturation and brightness of the pattern.

The principle lies in the reflection and scattering of light by white pigments (such as titanium dioxide), so that the underlying fabric does not affect the final pattern effect, thus obtaining a more vivid and pure color presentation.

White powders are generally formulated with a fine particle size to ensure even coverage at the edges and details of the pattern, while also providing a good degree of softness, making them suitable for light fabrics such as cotton T-shirts and sweatshirts, or for clothing that focuses on comfort.

Black DTF Powder

Black powder is mainly used for dark fabrics to enhance contrast between patterns and base colors. This makes details more prominent and edges sharper.

Black powder usually has a slightly coarser particle size than white powder. This can increase the pattern’s dimensionality and thickness. It is especially suitable for sportswear, denim, and fabrics needing high-contrast visuals, bringing strong visual impact to products.

However, when using it, match the particle size with the pattern’s complexity to avoid detail loss.

In addition, black powder is often used in designs where white ink should be hidden. As an alternative masking solution, it offers creative expression in specific scenarios.

Overall, white powder focuses on covering light bases and enhancing color saturation. It is delicate and soft, suitable for detailed patterns on lightweight fabrics. Black powder suits dark bases, enhancing edge clarity and contrast. With a slightly coarser texture, it is ideal for high-strength, abrasion-resistant fabrics. Correctly choosing between them ensures your finished products achieve optimal results.

Difference Between Various Coarseness and Fineness of DTF Powder

Besides color, DTF hot-melt powders are categorized into fine, medium, and coarse types based on particle size.

Powders of different particle sizes vary in transfer effect, design detail, and hand feel.

Fine powder has the smallest particles, suitable for designs with intricate details or thin lines, such as logos, small icons, or gradient patterns. It melts to form an even coverage with clear edges and a soft hand feel, ideal for lightweight fabrics like pure cotton T-shirts and baby clothes. However, control the temperature to avoid excessive powder penetration causing blurred edges.

Medium powder is a versatile type, balancing detail performance and adhesion, suitable for most cotton, polyester, and blended fabrics. With stable film formation and low error rates, it is the most commonly used type in small and medium workshops, fitting most regular designs and daily clothing production.

Coarse powder has larger particles, forming a thicker adhesive layer after melting, with strong adhesion and high wear resistance, suitable for thicker or heavy-duty fabrics like denim, sportswear, and workwear. However, it offers slightly poorer detail performance and a harder hand feel, unsuitable for small or complex designs.

In summary, fine powder suits delicate designs and emphasizes softness; Medium powder works for most regular applications; Coarse powder prioritizes firmness and wear resistance.

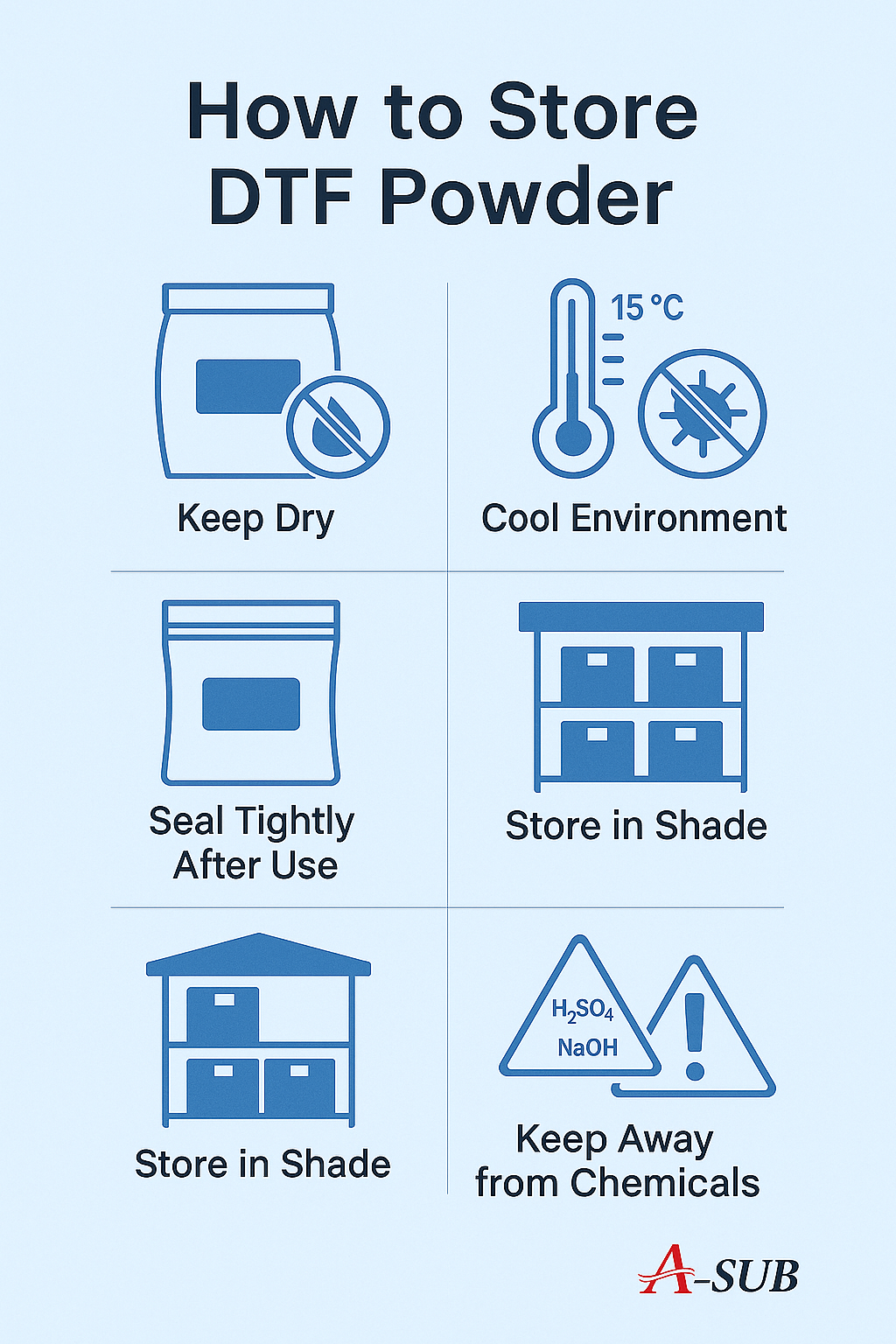

How to Store DTF Powder?

- Keep the storage area dry to prevent moisture and clumping.

- Store in a cool place to protect powder performance.

- Avoid direct sunlight to reduce UV damage.

- Seal the packaging tightly after use to block air and moisture.

- Ideal storage temperature is between 15°C and 27°C.

- Keep away from strong acids or alkalis.

DTF Powder FAQs

Q: What is the shelf life of DTF powder?

A: The general shelf life is about 12 months; store in a sealed package and avoid moisture. Expired powder may clump or degrade in performance, affecting transfer effects.

Q: Why does DTF powder clump?

A: Mainly due to moisture absorption from high humidity during storage. Keep the storage environment dry and prevent moist air from entering the package.

Q: What if the powder is unevenly distributed?

A: This issue might stem from overly large particles or improper settings of the powder spreading equipment. You should use the appropriate particle size and adjust the spreading uniformity to ensure even coverage of the ink layer.

Q: Can white and black powders be mixed?

A: We generally do not recommend mixing them, as their functions differ and blending may affect design effects and adhesion. Choose the appropriate color according to fabric color and design needs.

Q: Is DTF powder suitable for all fabrics?

A: DTF powder is mainly suitable for cotton, polyester, and similar fabrics. For special fabrics like nylon or blends, test adhesion first to ensure compatibility.

Q: How to handle powder residue after transfer?

A: You can remove excess powder by gently tapping or using a specialized brush. This helps to avoid affecting the appearance and hand feel of the finished product.

Conclusion

A-SUB focuses on providing stable and efficient consumables for a wide range of printing needs. Our hot melt adhesive powders are widely used around the world to improve the consistency and transfer quality of finished products.

For help selecting the right powder, please feel free to contact our technical support. We will recommend the best solution for your situation to ensure your business runs smoothly and upgrade quality.

发表回复