For enthusiasts of personalized printing and related enterprises, DTF (Direct to Film) printing and sublimation technologies are no strangers, each with its own advantages. Sublimation offers vibrant colors and durability but is only suitable for polyester fabrics; DTF is versatile for materials like cotton and blends but requires specialized pigment inks. Users often face a dilemma when choosing between the two.

Nowadays, A-SUB has launched a new sublimation DTF film, specially designed for users of sublimation printers. This film supports sublimation ink systems, eliminating the need to purchase expensive DTF-specific equipment and enabling high-quality transfers onto non-polyester materials such as cotton and canvas. This not only significantly reduces the technical and cost barriers for cross-material printing but also brings a flexible and economical innovative solution to creative enthusiasts and small-to-medium enterprises in the personalized customization field.

This article will take you closer look at this breakthrough product.

Technical Highlights: Why Can This DTF Film Handle Sublimation Ink?

Why Can’t Traditional DTF Film Use Sublimation Ink?

Traditional DTF films cannot directly use sublimation inks mainly because of the different transfer principles of the two. While sublimation works by vaporizing the dye and penetrating the fibers, DTF relies on pigment inks with a hot-melt adhesive layer to form the pattern. Sublimation dye molecules are not effectively immobilized by conventional DTF coatings, resulting in blurred transfer patterns and inadequate color fastness.

How Does The New Film Adapt to Sublimation Ink?

The core of this new product developed by A-SUB lies in its multi-layer coating structure. The surface coating is specially designed with good water absorption and thermal stability, which can effectively lock the dye molecules in sublimation inks and prevent premature volatilization or lateral diffusion during printing and preheating. At the same time, the film still retains the bottom coating structure combined with hot-melt powder to ensure that after powder sprinkling, baking, and heat pressing, the ink pattern can be completely and firmly transferred to the surface of non-polyester materials such as cotton and canvas.

This structure not only solves the adaptation problem of sublimation inks to coating affinity but also ensures the heat-pressing stability of the DTF process, forming a compatible closed loop between sublimation and DTF.

How Does It Differ From Traditional DTF Film?

Traditional DTF film coatings are hydrophobic and dry quickly, suitable for pigment inks but poor at adsorbing water-based dyes. The new compatible film uses a microporous hydrophilic coating that can firmly adsorb sublimation water-based inks while maintaining good bonding with hot-melt powder, balancing water absorption and thermal viscosity to achieve compatible use of the two inks.

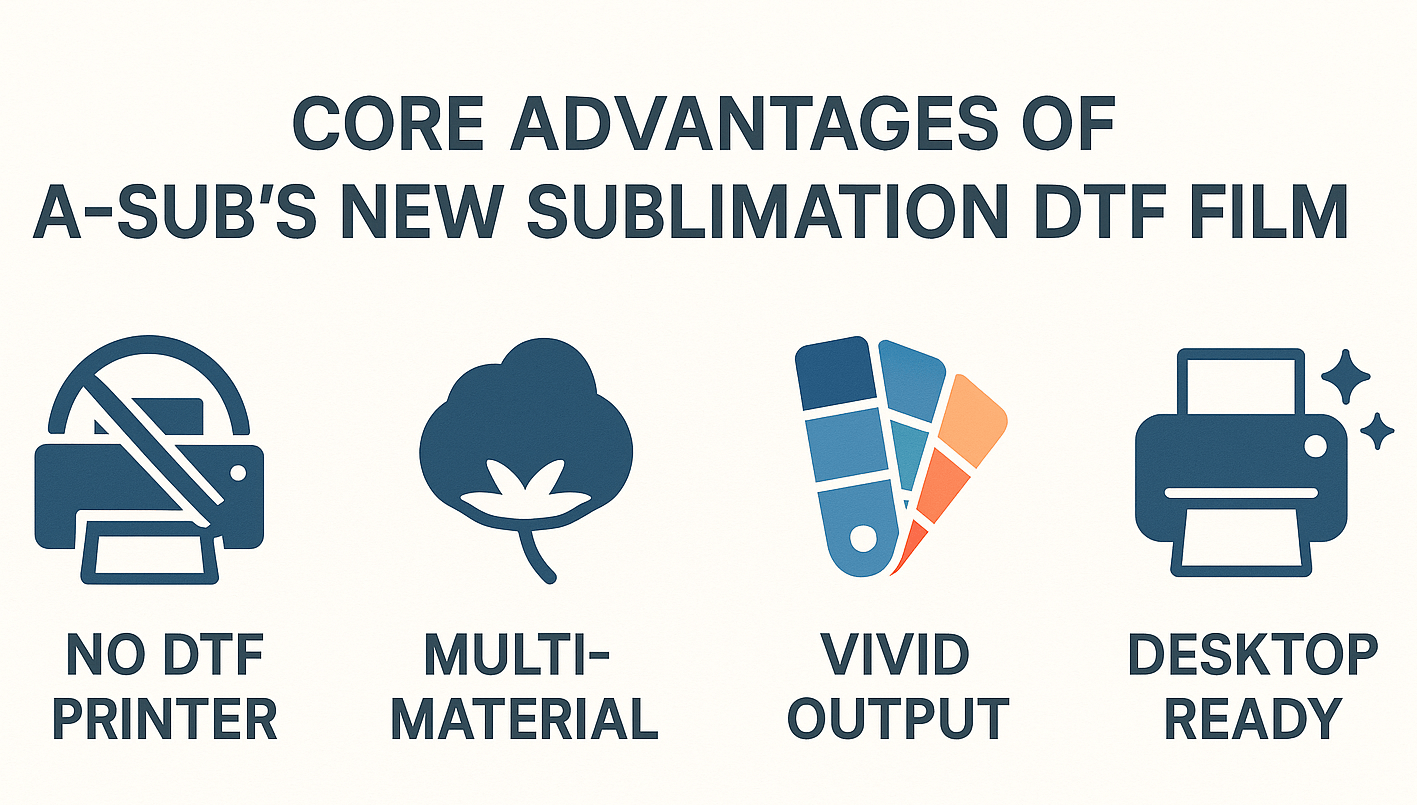

Core Advantages of Sublimation DTF Film

No Need for Specialized DTF Equipment

Under traditional methods, sublimation users must buy special inks and expensive DTF machines, which drives up procurement and maintenance costs. However, this new film breaks that barrier. You can use your existing sublimation ink and printer without extra supplies or complex adjustments. As a result, small workshops simplify inventory and control material expenses.

Broader Material Compatibility

You keep DTF’s wide-substrate advantage, yet gain the ability to print onto cotton, canvas, and other non-polyester fabrics.

Vibrant Color and Sharp Detail

Sublimation ink already offers a wider color gamut and finer particles. With this film, it still delivers rich hues and smooth gradients—perfect for detailed or complex designs.

Fits Desktop-Level Equipment, Lowers Entry Barrier

Many small makers and micro-studios own desktop sublimation printers like the Epson L8050 or L1800. By pairing one of those machines with this compatible film and hot-melt powder, they can start DTF printing at minimal extra cost.

Typical Application Scenarios

This sublimation DTF film excels in multiple use cases, such as:

Apparel & Home Textiles: Achieve full-color prints on T-shirts, sweatshirts, and canvas bags.

Customized Gifts: Decorate pillows, mouse pads, phone cases, and more with creative designs.

Signage & Decoration: Transfer onto non-woven, wood, acrylic panels, or decorative art pieces for branding and packaging.

These examples highlight the film’s flexibility, enabling both creative studios and print shops to expand their offerings without new equipment.

How to Use This Film with Sublimation Printers?

- Print Your Design

Use your sublimation printer and compatible ink to print the artwork onto the DTF film. - Apply Hot-Melt Powder

Evenly dust hot-melt powder over the printed image, then remove any excess. - Dry and Cure

Pass the film through a dryer or use hot air to solidify the powder. - Heat-Press Transfer

Place the film on your target material and press with a heat-press machine.

You only need a standard sublimation printer and heat press—no extra calibration required. For a full demonstration, please click to watch our video tutorial.

FAQs: What You Might Be Wondering?

Q: Can I use this film on any sublimation printer?

A: Yes. It’s designed for mainstream sublimation inkjets and heat-press machines without modification.

Q: Are the transferred images durable and washable?

A: Absolutely. The multi-layer coating ensures excellent colorfastness. You can wash the printed items just like regular sublimation garments.

Q: Why do colors look richer with this film?

A: Because it fully leverages sublimation ink’s wide color gamut and fine particle quality, resulting in deeper tones and smoother gradients.

Why Choose A-SUB?

- Proven Quality

With years of experience in printing materials, A-SUB enforces strict quality control. Our unique multi-layer coatings and premium raw materials guarantee consistent, long-lasting performance. - End-to-End Support

From pre-sale inquiries to after-sales troubleshooting, our technical team offers comprehensive guidance to both businesses and makers, continually refining best practices. - Reliable Supply Chain

We maintain a global warehouse network with ample stock. Whether you need samples or large orders, we deliver quickly to keep your production on schedule.

Conclusion

A-SUB’s sublimation DTF film opens up fresh possibilities for both the printing industry and creative users. By combining the vivid color of sublimation with DTF’s multi-material versatility, it makes personalized printing simpler and more accessible. Without extra equipment investment, you can use your existing sublimation printer to produce high-quality prints on cotton, canvas, and beyond.

Having passed rigorous tests, this film’s compatibility and reliability have won positive feedback. We believe that with A-SUB’s solution, businesses and creative studios alike will lower costs, boost efficiency, and bring their designs to life. Contact A-SUB today for samples or more information—and let’s start a new era of creative printing together!

发表回复